Trends in PV cells and modules

Module sizes and wafer sizes in transition

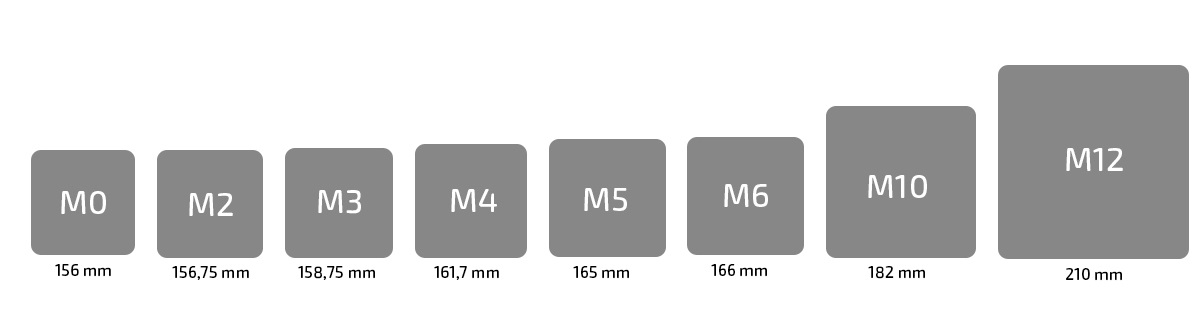

For more than ten years, the classic module with a cell size of 156 mm (M0 wafer), later 156.75 mm (M2 wafer), was considered as the standard module and was very popular.

The times when module dimensions have remained on the market over a longer period of time and could be established as a standard are now over. This became particularly noticeable at the beginning of 2020 when module producers from Asia started the trend towards ever larger module formats. Increasing wafer sizes are responsible for this.

As recently as 2018, 156.75 mm wafers accounted for about 80% of the market. In 2020, the upheaval came to 158.75 mm wafer sizes. The module outputs here range between 325 and 345 watts, and the dimensions are about 10 to 30 millimeters larger than a classic 60-cell module, depending on the design - so they are still very easy to move and process. However, the 158.75 mm cell, which was introduced only a few years ago, is already only available to a very limited extent.

A new size came onto the module market - M6 wafers with 166mm. In 2021, it turns out that this size has become the most widely installed module. This is a 120 cell with typically 350 to 380 watts.

But there seems to be no end in sight. The trend shows that it is possible to go even bigger. Wafer sizes of 182 mm (M10) and 210 mm (M12) have now arrived on the market. With the new cell sizes, a new power class is also emerging: M10-based modules have between 435 and 455 WP.

Source graphic: Trendforce

Trend and Outlook

According to the leading companies, modules with 182 mm wafers and 210 mm wafers are clearly superior to modules with smaller wafers in terms of manufacturing costs. Therefore, modules with these wafer sizes will probably prevail in the long term and make up the majority from 2022/2023.

Installers will also have to deal with this development. On the one hand, a certain increase in efficiency can usually be provided with the use of larger dimensions. On the other hand, handling according to the manufacturer's installation instructions is only one aspect that must be considered. Larger module areas set new requirements for the module installation and the substructure, which may have to be planned and executed completely differently, with the same or lower frame thickness. Our design tools for the substructure facilitate your planning and PV design - so feel free to use them.

The trend of larger solar modules has moved our partner K2 Systems to adapt its rail lengths. Now modules up to 1,170 mm width can be installed without any problems. You can find more information directly on the K2 website.

The following table gives you an insight into our portfolio with focus on standard modules. It helps you to find the right modules and to see the continuity. Please note that the availability refers to the availability in the market and the continuity of the products.

For further information, please contact your personal contact person at any time.