Double glazed holds up better

The advantages of double glass solar panels

Several solar panel manufacturers have shifted towards exclusively producing double glass solar panels – or plan to do this soon. Until now, this strategy was only a marginal phenomenon of single brands, but now Meyer Burger, Axitec, Luxor, and Trina are among the frontrunners in this transition. But what sets double glass solar panels apart from other types, and what are the advantages and disadvantages for electricians and solar professionals? In this blog post, we'll explore the world of double glass panels, their benefits, and how they compare to alternative solar panel types.

Table of Content

What are Double Glass Solar Panels?

Double glass solar panels replace traditional polymer backsheets with a glass layer on the back of the module. This design encapsulates the solar cells between two sheets of glass, providing unique advantages. While this technology can be used with both p-type and n-type cells, the latter tend to offer superior lifespan and performance. That’s why more and more glass-glass solar panels feature n-type cells with bifacial functionality, making them highly efficient.

The Advantages of Glass Glass Panels

Double glass solar panels offer a host of benefits:

- Material Durability: The primary advantage lies in the durability of the material itself. Glass has a remarkable resistance to aging, ensuring that these solar panels maintain their effectiveness over decades of use.

- Superior Solar Cell Protection: Double glass solar panels provide the best possible protection for solar cells. This robust shielding ensures that the modules continue to perform exceptionally well, even in the face of extended usage.

- Exceptional Robustness: These modules exhibit outstanding resilience against external factors and harsh environmental conditions like hail, making them a reliable choice for various installations.

- Transparency for Versatile Use: Double glass solar panels are particularly suitable for applications such as carports and conservatories, where aesthetics and functionality come together seamlessly.

In the following paragraphs, we will delve into a detailed comparison of the advantages of glass-glass solar panels in comparison to glass-backsheet panels.

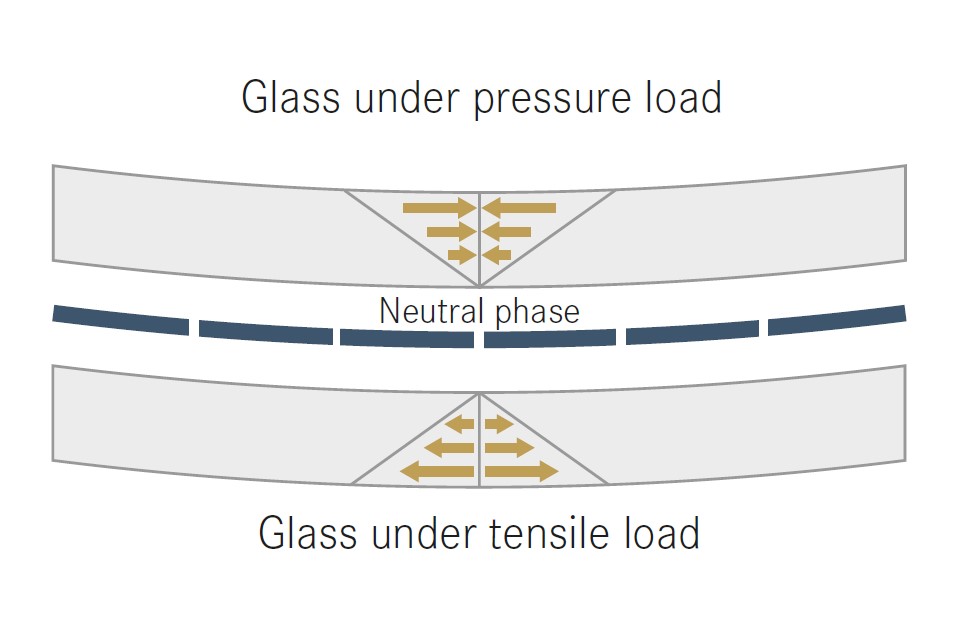

Robustness

One of the standout features of double glass solar panels is their exceptional resistance to mechanical loads. Thanks to the equal thickness of the front and rear glass sheets, these modules experience minimal compressive or tensile stress, ensuring optimal protection for the embedded solar cells. This robustness makes them ideal for various installations, even in challenging environments.

The thermal expansion of both glass layers is identical. Thus the solar cells are exposed to less stress in hot or cold conditions, as both glass layers expand and contract at the same rate.

Performance and Efficiency

The longer lifespan of double glass solar panels compared to glass-backsheet panels results in significantly higher overall yields for the solar system over its lifetime. This is crucial in ensuring the long-term profitability. Bifacial solar panels, when appropriately installed and under favorable conditions, can achieve even higher efficiencies.

Safety

Despite the thinner front glass sheet, double glass modules maintain stability due to their total thickness of approximately 4 mm of glass. This design also offers superior protection from humidity, ammonia, salt spray, and even fire, making them a safer choice for long-term installations.

Eco-friendly

The longer lifespan of double glass modules results in proportionally less waste generation. Due to their construction as and the recyclability of the materials used, these modules are theoretically more environmentally friendly than conventional material combinations. However, in practice, recycling potential has been underutilized. Glass from solar panels is primarily used for producing glass wool, which cannot be further recycled.

If progress is made in the recycling of solar modules in the next 30 years, double glass solar panels are likely to become somewhat more environmentally friendly than other panel types.

Disadvantages of double Glass solar panels

While double glass solar panels come with numerous advantages, it's essential to consider potential drawbacks as well:

- Higher weight: Glass glass solar panels tend to be heavier due to the double glass sheets. However, modern modules can feature thinner glass, mitigating this issue. In many cases, the weight difference isn't significant.

- Mounting challenges: Solar panels with higher weight can be more challenging to mount, potentially increasing installation costs.

- Cost consideration: Double glass solar panels can be more expensive than other solar panel types, especially when installation costs rise due to their weight.

Glass glass compared to other module types

Glass backsheet solar panels

Panels with backsheet were the standard for a long time. Some manufacturers are transitioning to glass glass due to its superior long-term performance, even though glass backsheet solar panels can be cheaper and lighter.

Bifacial solar panels

Both glass-glass and glass backsheet solar panels can utilize bifacial technology, collecting energy from the backside. This can be advantageous in solar parks. Also, terrace or carport roofs, exposed to the low-lying sun could benefit from bifacial panels. In these cases, however, double glass solar panels excel, due to safety and design reasons.

The most important brands

Meyer Burger

Meyer Burger is a Swiss company with module and cell production in Europe. The premium manufacturer places great emphasis on research and sustainability. The double glass solar panels are among the most powerful, especially in the long term: Meyer Burger guarantees a performance of at least 93.2 percent after 30 years – as much as no other manufacturer in our portfolio.

Luxor

The German manufacturer produces in Europe and Asia. The bifacial solar panels with heterojunction technology offer an especially high bifaciality factor of 95 percent. This means that the efficiency of the back side reaches 95% of the efficiency of the front side. With appropriate mounting, these modules can therefore yield particularly high performance. Moreover, the solar panels are considered to be PID-free and partially also LID-free. As such, they are only subject to age-related degradation.

DAS Solar

The DH108NA series panels are the lightest glass-glass modules in our portfolio and, at just over 20 kilograms, are almost ten kilos lighter than the heaviest ones. The efficiency under test conditions is at least 22.3 percent – the top value in our portfolio, which only two other manufacturers achieve.

Solitek

Solitek tests its solar panels with particularly high pressure and suction loads. The manufacturer offers a 30-year product warranty for its stable panels – not every manufacturer can keep up with that. The portfolio also includes a frameless solar panel. Due to the lack of a frame, it is only 7 millimeters thick, but the two glass panes, at 3 millimeters, are the thickest compared to the other modules in the Krannich Webshop. Thanks to the thick panes, the solar panel withstands particularly high loads, with test values of 10,500 Pa snow load and 5,400 Pa wind load, almost twice as high as most other solar panels.

Trina Solar

The double glass solar panels of the Vertex S and S+ series achieve good to very good results in all areas compared to other panels in the Krannich portfolio. For example, they are among the lightest solar panels and those with the best performance. Also, the promised performance until the end of the 30-year performance warranty is relatively high.

Talesun

With 450 watts, the TD6I72M series offers the highest nominal power among all glass-glass solar panels in our portfolio. However, the panels in this series are also particularly large and comparatively heavy.